At Jayshree Tablet Science, we make precise tools for the pharmaceutical and Health industries. With our Tablet Punch Polishing Machine, your tablet punches and dies are always in great condition - leading to increased productivity, less sticking, and longer tooling life.

The polishing system is small, dependable, and made for uniform results. It offers the ideal mirror or matte finish, ensuring that you keep the best tablet quality through all the production cycles.

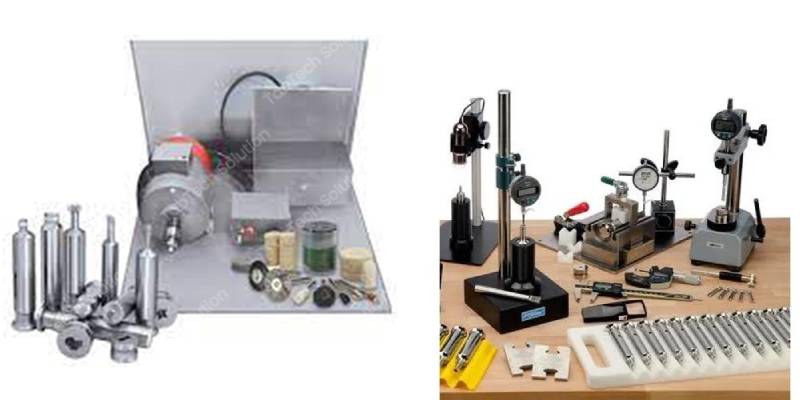

Tablet Punch Polishing Kit – Complete Finishing Solution

The Tablet Punch Polishing Kit that we offer contains all necessary supplies for the maintenance team to perform cleaning, buffing, and polishing operations in an efficient manner. This kit, which consists of a stainless steel-covered 0.5 HP single-phase polishing machine, is designed for high performance and extended service life.

The Tablet Punch Polishing Kit is a comprehensive package that contains all the tools necessary for an effective routine maintenance of punches—cleaning, buffing, and polishing. The 0.5 HP single-phase polishing machine with a stainless steel cover is at the center of this kit, thereby, ensuring magnificent performance and long service life.

Kit Components:

- Polishing Machine 0.5 HP Single Phase (S.S. Cover) – 1

- 8 x 1 Cloth Buffing Wheel – 1

- 8 x 2 Cloth Buffing Wheel – 1

- 8 x 1 Matt Polish Wheel – 1

- 8 x 1/2 Matt Polish Wheel – 2

- Wire Brush – 1

- Black Ball Brush – 1

- Green Luster – 6

- Black Luster – 2

- Diamond Paste 0# – 2

- Diamond Paste 3# – 2

- Black Cup Brush Tip Polish – 15

- White Disc Brush Tip Polish – 15

- Flat Cotton Bob – 15

- Conical Cotton Bob – 15

- 150 No. Hammery Paste – 1

- Hammery Stick – 2

- 320 & 120 No. Paper Roll – 1 + 1

Every accessory is chosen to provide a smooth, flawless finish — reducing wear and maintaining exact punch dimensions.

Tablet Inspection Kit – Precision Testing Made Easy

Quality control starts with accurate measurement. Our Tablet Inspection Kit (also known as Punch Inspection Kits) allows you to verify punch and die dimensions with precision tools designed for the highest manufacturing standards.

Inspection Kit Includes:

- 0–25 mm Micrometer

- 25–50 mm Micrometer

- 0–150 mm Dial Vernier

- Dial Gauge (0.01 mm Least Count)

- Magnetic Stand for Dial

- 0–7 mm Radius Gauge

- 7.5–15 mm Radius Gauge

- 15.5–25 mm Radius Gauge

- Magnifying Glass

- Punch Head Go-No Go Gauges (D & B Type)

- Punch Height 133.6 mm Standard Gauge

- Punch Holder “D” Type

- Punch Holder “B” Type

- Die Hole Gauge (6 / 6.5 / 7 / 8 / 9.5 / 10 / 11 / 12.7 mm)

- Rotor Die Hole Checking Gauge “D” Type (38.10 / 38.11 / 38.12)

- Rotor Die Hole Checking Gauge “B” Type (30.16 / 30.17 / 30.18)

- Rotor Die Hole Checking Gauge “BB” Type (24.00 / 24.01 / 24.02)

- Surface Plate

This combination of instruments helps identify wear, confirm tolerances, and maintain consistent tablet thickness and shape.

Why Choose Jayshree Tablet Science?

- Expertly designed Tablet Punch Polishing Machines for long-lasting performance

- Comprehensive Punch Polishing Kits with all required accessories

- Precision-tested Tablet Inspection Kits for quality assurance

- Backed by technical expertise and after-sales support

Enhance Tablet Quality with Precision Tooling

In Jayshree Tablet Science, we hold that every detail is significant — polishing, for instance, or checking. Your tablets and dies will always produce uniform results thanks to our machines.