In pharmaceutical tablet manufacturing, most production problems do not start with machines. They usually start with tooling. Anyone who has spent time on a tablet production floor knows this. Punches and dies are the components that actually do the work. They stay inside the tablet die press for hours, sometimes days, handling constant pressure and movement.

When tooling quality is good, production runs smoothly. Operators do not need to make frequent adjustments. Tablets come out consistent. When tooling quality is poor, issues show up quickly. Weight variation, sticking, rough tablet edges, embossing problems - all of these are common signs. This is why tablet press dies and punches play such an important role in pharmaceutical manufacturing.

At Jayshree Tablet Science, our tooling is designed based on real production experience, not just drawings and specifications.

What Are Punches and Dies in Tablet Manufacturing?

Punches and dies are the main forming parts of a tablet compression machine. The die determines the tablet’s diameter and shape. The upper and lower punches compress the material inside the die cavity.

During actual production, punches and dies are exposed to high mechanical load, friction, and continuous movement. If tooling surfaces are not finished properly or dimensions are not accurate, tablets will start showing defects. This is why manufacturers depend on reliable dies & punches for tablet compression machine use to keep production stable.

In pharmaceutical manufacturing, tooling accuracy directly affects dosage control. Even a small variation in punch length or die bore can impact tablet weight.

How the Tablet Die Press Works

A tablet die press works in a simple cycle, but stability depends on tooling condition. Powder fills the die cavity. The lower punch controls how much material enters. The upper punch compresses the material. The lower punch then ejects the tablet.

In rotary presses, this cycle repeats continuously at high speed. Over time, any weakness in tooling shows up. Sticking, binding, or rough ejection usually means punches or dies need attention. Well-manufactured tablet press dies and punches help maintain smooth operation throughout long production shifts.

Tablet Press Dies and Punches by Jayshree Tablet Science

Jayshree Tablet Science manufactures punches and dies for different tablet types and production requirements. Our approach is practical — tooling must perform consistently, not just look good when new.

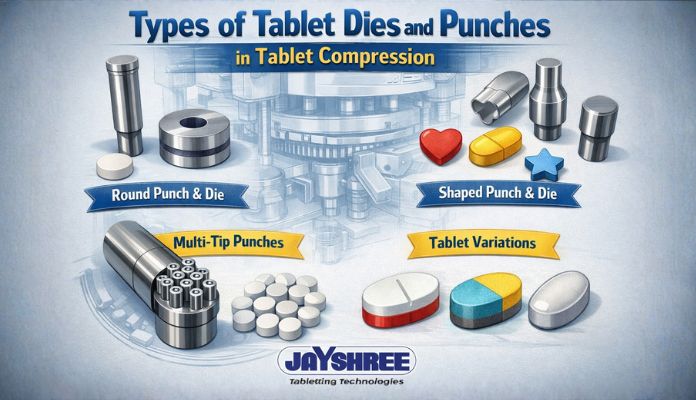

Round Shape Tablet Toolings

Round Shape tablet toolings are commonly used because they are stable and easy to run at high speed. They allow uniform compression and smooth ejection. In high-volume pharmaceutical production, round tablet press dies and punches are preferred for their reliability and predictable performance.

Shaped & Special Tablet Toolings

Shaped tablets toolings are often required for branding or patient convenience. These include oval, capsule-shaped, square, and logo-engraved tablets. Shaped tooling requires careful machining. Even small errors affect embossing clarity and tablet finish.

Shaped Tablet dies & punches for compression machine applications must balance sharp detailing with durability. At Jayshree Tablet Science, special toolings are manufactured with controlled tolerances to ensure consistent results.

Multi Tip Tablet Toolings

Multi tip tablet toolings are used when higher output is needed without adding machines. Multiple tablets are produced in one compression cycle.

For multi tip tablet press dies and punches, uniformity across all tips is critical. If one tip differs, tablet weight variation becomes visible. Precision manufacturing and proper alignment are essential for stable production.

Bolus Tablet Toolings

Bolus tablet toolings are designed for large tablets, mainly used in veterinary and nutraceutical industries. These tablets require higher compression force.

Bolus dies & punches for tablet compression machine use are manufactured with stronger construction to handle heavy loads while maintaining tablet shape and strength.

Carbide Lined Dies

Carbide lined dies are commonly used for abrasive formulations or long production runs. Abrasive materials wear standard dies faster, which affects tablet dimensions over time.

Carbide lining improves wear resistance and helps maintain die accuracy during extended operation.

Sealed Groove Punches

Carbide lined dies are commonly used for abrasive formulations or long production runs. Abrasive materials wear standard dies faster, which affects tablet dimensions over time.

Sealed groove punches help prevent powder from entering punch head areas. Powder ingress leads to internal wear and contamination.

Using sealed groove punches improves cleanliness and extends the service life of tablet press dies and punches, especially in pharmaceutical environments.

| Tooling Type | Description | Key Benefits | Typical Applications |

|---|---|---|---|

| Round Tablet Toolings | Standard round punches and dies used for high-speed tablet production | Stable compression, smooth ejection, consistent tablet quality | High-volume pharmaceutical tablet manufacturing |

| Shaped & Special Tablet Toolings | Toolings for oval, capsule-shaped, square, or logo-engraved tablets | Clear embossing, accurate shape, improved brand identity | Branded pharmaceutical and patient-friendly tablets |

| Multi Tip Tablet Toolings | Multiple tips produce more than one tablet per compression cycle | Higher output without adding machines, improved efficiency | Large-scale pharmaceutical production |

| Bolus Tablet Toolings | Heavy-duty punches and dies for large tablet sizes | Handles high compression force, maintains tablet strength | Veterinary and nutraceutical tablets |

| Carbide Lined Dies | Dies with carbide lining for enhanced wear resistance | Longer tooling life, stable dimensions in long runs | Abrasive formulations and extended production cycles |

| Sealed Groove Punches | Punches designed to prevent powder ingress into punch head | Reduced contamination, less internal wear | Clean pharmaceutical manufacturing environments |

| Customized Toolings | Toolings manufactured as per tablet design and machine type | Better performance, fewer production issues | Special tablet designs and formulations |

Applications of Punches and Dies in Pharmaceutical Manufacturing

Punches and dies manufactured by Jayshree Tablet Science are used in pharmaceutical, nutraceutical, herbal, veterinary, and specialty tablet production. Each application has different requirements related to tablet size, formulation, and compression force.

Reliable tooling helps manufacturers manage these differences without frequent production interruptions.

Importance of High-Quality Dies & Punches

High-quality tablet press dies and punches reduce production issues such as tablet defects, excessive wear, and frequent adjustments. Stable tooling allows operators to maintain consistent machine settings.

Over time, this results in better productivity and lower operational costs.

How to Choose the Right Tooling for Your Tablet Die Press

Tooling selection depends on tablet design, formulation properties, machine type, and production volume. Choosing the right dies & punches for tablet compression machine use helps avoid unnecessary problems during production.

With years of tooling manufacturing experience, Jayshree Tablet Science supports customers in selecting suitable tooling solutions.

Maintenance Tips for Tablet Press Dies and Punches

Tooling life depends heavily on maintenance. Regular cleaning, inspection, and proper handling extend the working life of tablet press dies and punches.

Preventive maintenance also helps maintain consistent tablet quality and avoids unexpected downtime.

Choosing the Right Tablet Press Tooling

Punches and dies are central to pharmaceutical tablet manufacturing. Whether producing round tablets, shaped tablets, multi-tip tablets, bolus tablets, or using carbide-lined tooling, precision and durability remain essential.

At Jayshree Tablet Science, we manufacture dependable dies & punches for tablet compression machine operations, focusing on real production performance and long-term reliability

Frequently Asked Questions (FAQs)

1. What punches and dies do you supply?

We supply round, shaped, multi tip, bolus, carbide lined dies, and sealed groove punches used in daily pharmaceutical production.

2. How do I select dies & punches for my tablet compression machine?

It depends on tablet size, formulation, and machine condition. One type does not suit every setup.

3. Are your punches compatible with different tablet die press models?

Yes. Our tooling works with most standard tablet die press machines, including rotary presses.

4. When should carbide lined dies be used?

When formulations are abrasive or tooling wear becomes frequent during long production runs.

5. Do you provide customized tablet press dies and punches?

Yes. We make standard as well as customized tooling based on tablet and production needs.