Tablet production is an important process in the pharmaceutical industry that demands accuracy, repeatability and efficiency. Tablet compression is one of the most critical steps in tablet manufacturing and it highly relies on the quality of the compression tooling. Tablet Dies and Punches are the central parts of tablets that cause to obtain the precise shape, size and strength. It is necessary to learn about the kinds of punches and dies on a tablet press in order to assure quality production as well as ensure an uninterrupted process.

In this article, we will break down what a tablet press die is along with the tablet die punch and types of punches used in tablet compression and how it is used. We also feature Jayshree Tablet Science providing dependable Tablet Punching Machine solutions to the pharmaceutical sector.

Tablet Press Dies in Tablet Compression

The configuration of the tablet press die plays a key role in influencing the physical properties of a tablet. They determine compression diameter, thickness and general geometry of the tablet..

What Are Tablet Press Dies?

tablet press die is the precision machine component to form the powder and it is called as tableting tooling or tablet pressing dies. The powder or granules are fed into the die cavity and then compression is applied. Tablet size and uniformity are directly affected by the internal dimensions of tablet press dies, so precision die manufacturing is critical.

Functions of Tablet Press Dies in Tablet Compression

The main functions of tablet press die include:

- Maintaining accurate tablet shape and size

- Supporting uniform tablet weight

- Holding powder securely during compression

- Reducing tablet defects such as capping and lamination

High-quality tablet press dies improve production efficiency and extend tooling life.

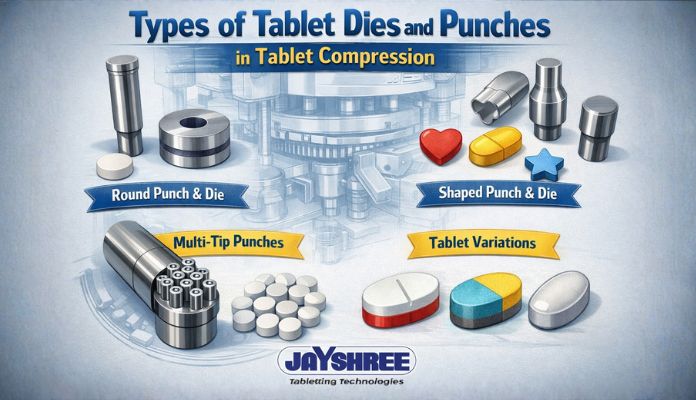

Types of Tablet Press Dies Used in Tablet Compression

Different formulations and production requirements require different types of tablet press dies, such as:

- Round Tablet Press Dies

Commonly used for standard round tablets in pharmaceutical production, these dies ensure uniform tablet size, weight, and finish. They are suitable for a wide range of formulations and provide stable performance during continuous production. - Shaped Tablet Press Dies

Used for oval, capsule-shaped, square, or customized tablets with logos, these dies help create visually distinct tablets. They are ideal for branding, easy identification, and maintaining accurate tablet shape and consistency. - Carbide Lined Tablet Press Dies

Ideal for abrasive formulations and high-speed tablet compression, these dies offer excellent wear resistance and longer service life. They help reduce downtime while maintaining precise tablet dimensions over long production runs. - Multi Tip Tablet Press Dies

Designed for high-speed production, these dies allow multiple tablets to be compressed in one cycle. They help increase output, improve machine efficiency, and are well-suited for large-scale manufacturing.

What Is a Tablet Die Punch?

A tablet die punch is a component of the tooling that shifts within the die cavity during the squeezing process. The machines for tablet compression utilize punches at both ends to exert pressure and create tablets. The tips of the punches decide the surface design, embossing, and scoring of the tablets.

Role of Tablet Die Punch in Tablet Compression

The tablet die punch takes over a variety of important tasks:

- Transforming powder into compact solid tablets

- Regulating tablet thickness and hardness

- Producing logos, score lines, and engraved markings

Appropriate tablet die punch design not only guarantees consistent tablet quality but also promotes smooth operation of the machine.

Types of Punches in Tablet Compression

There are various types of punches in tablet compression, each designed for specific tablet requirements:

Carbide Tip Punches:

Carbide Tip Punches are designed for high wear resistance and long service life in tablet production. They are ideal for hard and abrasive formulations, helping maintain consistent tablet quality while reducing tool replacement frequency.

Special Purpose Punches:

Special Purpose Punches are manufactured to meet specific tablet designs, shapes, or functional requirements. These punches are used when standard tooling is not suitable and help achieve precise and customized tablet results.

Multi Tip Tablet Punches:

Multi Tip Tablet Punches allow the production of multiple tablets in a single machine stroke, increasing overall output. They are suitable for high-volume manufacturing and help improve production efficiency.

Difference Between Tablet Press Dies and Tablet Die Punch

Press dies and die punches cooperate in compression happenings, but their functions during a compression process often differ.

How Tablet Press Dies and Tablet Die Punch Work Together

The dies of the tablet press maintain the powder inside the cavity of the die, while the punch of the tablet die exerts compressive force from above and below. Precise alignment of the dies of the tablet press and the punch of the tablet die is the key to getting tablets without any defects.

Importance of Correct Tablet Press Dies and Tablet Die Punch Selection

Incorrect selection of tablet press dies or tablet die punch can lead to:

- Tablet weight variation

- Surface defects and breakage

- Increased machine wear and downtime

Choosing the right tooling ensures consistent tablet quality and efficient production.

Choosing the Right Types of Punches and Dies in Tablet Compression

Selecting the correct types of tablet dies and punches in tablet compression is essential for achieving optimal tablet performance.

Factors Affecting Selection of Tablet Press Dies

Key factors include:

- Tablet size and shape requirements

- Tablet compression machine specifications

- Production volume

- Powder and granule properties

Factors Affecting Selection of Tablet Die Punch

Important considerations include:

- Required tablet hardness and thickness

- Embossing and scoring requirements

- Tool material and wear resistance

- Compression force limits

How Types of Punches in Tablet Compression Impact Tablet Quality

The dies of the tablet press maintain the powder inside the cavity of the die, while the punch of the tablet die exerts compressive force from above and below. Precise alignment of the dies of the tablet press and the punch of the tablet die is the key to getting tablets without any defects.

Tablet Dies and Punches Offered by Jay Shree Tablet Science

Jayshree Tablet Science is a trusted supplier of high-quality tablet compression tooling for pharmaceutical manufacturers.

Standard Tablet Press Dies and Tablet Die Punch

Jayshree Tablet Science provides standard tablet die and punches that are manufactured according to industry specifications. These tools are designed to ensure precision and reliability and are compatible with a wide range of tablet compression machines, helping manufacturers achieve consistent tablet quality and efficient production.

Customized Types of Punches in Tablet Compression

For special requirements, Jayshree Tablet Science also provides customized types of punches in tablet compression, including logo punches, multi-tip punches, and special-shaped dies.

Quality Standards Followed by Jayshree Tablet Science

Jayshree Tablet Science follows strict quality standards, including:

- Use of high-grade tool steel

- Precision machining and polishing

- Thorough inspection for dimensional accuracy

This ensures long tool life, consistent performance, and reliable tablet production.

Skillfully manipulating the tablet press dies, tablet die punch, and various punches in the compression process is the primary factor in the production of high-quality, uniform tablets. Selecting the proper tooling not only brings about the finest tablet quality but also aids in reducing production issues and increasing productivity. Jay Shree Tablet Science, with its know-how, precision engineering, and dedication to quality, provides trustworthy tablet compression solutions that allow drug makers to ensure hassle-free production and uphold the highest standards in tablet production.