The tablet manufacturing process in the pharmaceutical sector relies on high durability and extremely precise quality control. Every single tablet produced should have the same weight, hardness, and appearance. Modern tablet dies and punches are the main tools behind the successful production process because they allow for a great deal of production efficiency while at the same time cutting waste and contributing to the long-term operational efficiency of the industry.

What Are Tablet Dies and Punches?

Tablet dies and punches are the most important materials that are employed to create tablets during the tablet compression process; these are the main tools that make size and shape uniform for the tablets. Thickness, hardness, and surface finish of the tablets are very much determined by these tools. Consistent tablet quality across large-scale production is guaranteed through precision-engineered tooling.

Importance of Tooling in Pharmaceutical Manufacturing

Tooling is one of the most important components in pharmaceutical manufacturing, as it enables accurate dosing and consistency from one production batch to the next. Tooling that can be depended on lowers the variability of the process and helps to meet the regulatory requirements. Manufacturers who use high-grade tablet punches and dies have increased productivity, and the manufacturing process is stable.

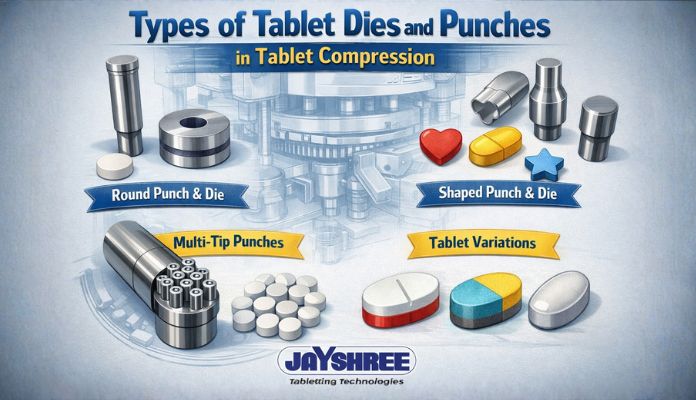

Types of Tablet Dies and Punches

In terms of configuration, tablet dies and punches come in different forms to assist with the various production needs, including single-station and multi-station tablet presses. Tooling can also be made to measure depending on the specific requirements of the tablet shape, size, and formulation. Jayshree Tablet Science has versatile tooling solutions that meet the needs of different pharmaceutical applications.

Advanced Manufacturing Technology

The production of modern tablet tooling involves the application of advanced CNC machining and precision finishing techniques. The use of top-quality materials combined with stringent quality control measures makes the tools very durable and their lifespan very long. The technologies at Jayshree Tablet Science reduce downtime and maintenance, all while keeping the performance level consistent.

High-Performance Compression Components

Tablet punches serve the purpose of exerting appropriate and equally distributed compression forces throughout the process of tablet formation, making sure that the resulting tablets have smooth surfaces and consistent hardness. The proper design of punches greatly helps to avoid such defects as sticking, capping, and chipping; hence, the output is stable, and production efficiency is improved.

Meeting Pharmaceutical Quality Standards

The punches and dies used in the tablet-making process of the pharmaceutical industry must conform to the international quality and regulatory standards. These parts are very important in the proper dosage control and consistent tablet quality, which are necessary for regulatory approvals and patient safety.

Compatibility with Tablet Press Machines

Tablet press dies are not only designed with accuracy but also precision engineered to fit perfectly with the corresponding tablet press machine, resulting in smooth operation and great production rates. Jayshree Tablet Science, a tablet tool designer, creates tools that minimise powder loss, increase tablet density, and provide reliable performance even when operating in high-speed manufacturing environments.

Maintenance and Tool Longevity

Proper maintenance can greatly increase the life of tablet tooling. It is through regular cleaning, inspection, and prompt servicing that one can avoid unexpected breakdowns. The tooling produced by Jayshree Tablet Science comes with the feature of easy maintenance and delivers consistent tablet quality for the duration of the long production cycles.

Why Choose Quality Tooling Solutions

Tablet tooling of high quality leads to increased performance, lowered rejection rates, and reduced overall production costs in the long run. The application of precision engineering and the use of durable materials are the factors that guarantee reliable operation in the harsh conditions of pharmaceutical manufacturing.

The Future of Pharmaceutical Tablet Tooling

Innovation, advanced materials, and optimised tooling designs are the traits of future tablet manufacturing. The next generation of pharmaceutical production is being represented by enhanced coatings, improved geometries, and automation-ready solutions.

Conclusion

Purchasing high-quality punches and dies is a prerequisite for the efficient production of pharmaceutical tablets. The precision-engineered tools used to produce tablets are not only...

Frequently Asked Questions (FAQs)

1. What are tablet dies and punches used for?

Tablet dies and punches are used in tablet compression machines to shape and form tablets with uniform size, thickness, and finish during pharmaceutical production.

2. What is the function of tablet punches in tablet manufacturing?

Tablet punches apply compression force to the powder inside the die cavity, helping achieve consistent tablet hardness and surface quality.

3. What are punches and dies in pharmaceutical production?

Punches and dies in pharmaceutical manufacturing are precision tools responsible for accurate dosage control and consistent tablet formation across production batches.

4. What are tablet press dies, and why are they important?

Tablet press dies are fitted into tablet press machines to hold the powder during compression, ensuring stable tablet shape and density at high production speeds.

5. What does a tablet die punch do in a tablet press machine?

A tablet die punch works with the die cavity to compress powder into tablets, directly affecting tablet size, hardness, and overall appearance.