Precision, consistency, and efficiency are the main characteristics of the pharmaceutical industry in the production of solid dosage forms. The Tablet Press Machine is the most important piece of equipment in the whole process. At Jayshree Tablet Science, we offer advanced tablet compression solutions that enable the manufacturers to produce high-quality tablets with a uniform dosage and nice finish.

This machine is tableting machine and it is essential for the process of turning powder or granule substances into tabs that are not only in the proper size but also meet the cleanliness and other requirements of the world.

What is a Tablet Press Machine?

Tablet Press Machine is a piece of pharmaceutical equipment that compresses powders or granules to make tablets of the same size and weight. This machine operates in a way that the right amount of pressure is applied, and the resulting tablets have the desired strength, weight, and quality.

Jayshree Tablet Science manufactures tablet presses that provide great reliability not only to pharmaceutical industries but also to nutraceutical and herb manufacturers because of their long service life.

How Does a tablet compression machine Work?

The operation of a tablet compression machine is based on the principles of mechanical compression with the use of punches and dies. The steps of the process are:

- Filling – The powder or granules are fed from the hopper into the die cavity..

- Compression – The upper and lower punches compact the material into tablets.

- Ejection – The finished tablets are ejected from the die cavity

The process demands precision tooling and this is the reason why Jayshree Tablet Science is committed to providing high-quality tablet tooling machine solutions for achieving the best possible compression results.

Types of Tablet Press Machines

Tablet press machine can be customised based on application requirements. The machine selection is based on factors like the output requirement, the area of application and need of formulation. Here are the most popular types and what they're used for.

1.Single Punch Press Machine

Single Punch Machine is suitable for small-batch production and hospitals, labs to do tablet research. It presses one tablet at a time, so it’s great for situations where accuracy and control are more important than speed.

At Jayshree Tablet Science, this machine is engineered for convenience and durability that's why it has become the first choice of laboratories, research centers and startups. New formulations can be tested, tablet weight and hardness checked, parameters perfected before scaling up to larger production systems.

2. Rotary Press Machine

The Rotary Press Machine is designed for high volume production of tablets. Several compression stations turn simultaneously to enable uninterrupted and constant production of the tablets.

This product can be found in pharmaceutical processing plants that rely on uniformity shop floor-friendly mobile design with the highest bending capacity. By maintaining consistent tablet weight, thickness and hardness for larger batches, it guarantees smooth production runs that are also easy to scale. Jayshree Tablet Science’s line of rotary press machines are designed for high production output as well as long life.

The R&D Press Machine is specifically developed for research, product development and small scale production. By enabling pharmaceutical teams to try different formulations, compressions forces and tooling set-ups before making a full-scale commitment.

In Jayshree Tablet Science R & D Equipments, our machines are versatile to meet different size of tablet by changing the basic components. They assist manufacturers in assessing tablet properties, including weight variation, hardness and thickness to make informed decisions prior to scale-up.

4. Confectionary Press Machine

The Confectionary Press Machine is applicable to the candies, biscuits lozencies and it's able to produce tablets for pharmaceuticals. They so need aesthetic appearance - smooth surface, constant form, and homogeneous pressing.

Highly utilized in food & confectionery production units, the machine is designed to maintain hygiene and continual quality over large batches. Jayshree Tablet Science confectionary presses are designed to process extremely delicate materials with complete confidence in the finished products' appearance and quality.

Key Components of a Tablet Press Machine

What is known is a common tablet press, which comprises

- Hopper

- Feed frame

- Upper and lower punches

- Dies

- Compression rollers

- Ejection cam

- Control panel

Every part is designed for accuracy and endurance in the Jayshree Tablet Science Product, providing more tablet quality for a longer period of time without taking your machine out of production.

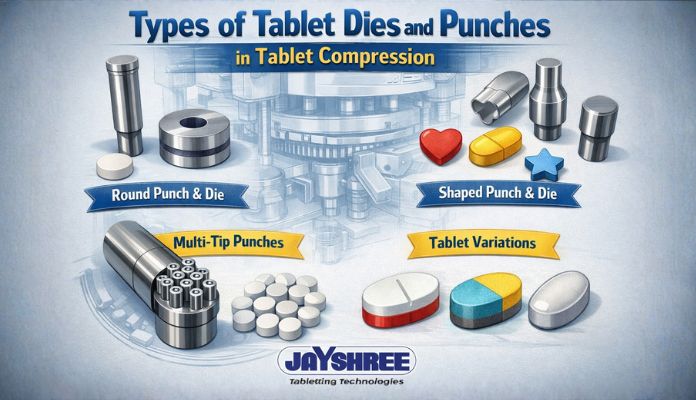

What is tablet tooling machines?

Tablet tooling is the dies and punches that determine a tablet's overall size, shape, and whether the product will be embossed. A high-performance tablet tooling machines is vital for tablet appearance, hardness, and productivity.

Common Tooling Types:

- B Tooling

- D Tooling

- BB Tooling

At Jayshree Tablet Science, We manufacture of all types of tablet tooling (tablet compression tools) for any make of tablet tooling machines .

Applications of Tablet Press tooling

Tablet press tooling from Jayshree Tablet Science: Our tablet compressing machine has its applications in several industries, such as

- Pharmaceutical manufacturing

- Nutraceuticals and dietary supplements

- Herbal and ayurvedic products

- Veterinary medicines

- Chemical and food industries

Benefits of Our Tablet Press tooling

- High production efficiency

- Accurate dosage and uniform tablet weight

- Reduced labor costs

- Scalable production capacity

- GMP-compliant manufacturing

From Jayshree Tablet Science, a dependable tablet press tooling ensures high-quality tablets with every production.

Factors to Consider When Choosing a Tablet Press tooling

Before you choose a tablet press, think about these:

- Production output requirements

- Tablet size, shape, and formulation

- Tooling compatibility

- Maintenance and operational ease

- Compliance with pharmaceutical standards

At Jayshree Tablet Science, we offer expert guidance to help you select the tablet press that’s right for you.

Common Tablet Compression Problems and Solutions

|

Problem |

Cause |

Solution |

|

Capping |

Air entrapment |

Optimize compression force |

|

Sticking |

High moisture |

Improve granulation |

|

Weight variation |

Poor powder flow |

Adjust feed system |

|

Tool wear |

Low-grade tooling |

Use premium tooling from Jayshree Tablet Science |

Trends in the Future of Tablet Presses

The tableting industry has seen continuous advancements in:

- Automation and smart controls

- Industry 4.0 integration

- Advanced tablet tooling technology

- Energy-efficient tablet compression machine

Jayshree Tablet Science is leading the way forward with its hi-tech, modern ideas and innovative designs.

Conclusion

Tablet Press Machine - The Heart of the Pharmaceutical Tableting Process.

A tablet press is the core equipment in the tablet manufacturing process. By selecting a top-of-the-line tablet press machine and precision tablet tooling from Jayshree Tablet Science, manufacturers can expect to deliver higher-quality products more efficiently with full compliance in mind.

We at Jayshree Tablet Science promise to deliver the best tablet press machines across the world.